Factors to Consider for Efficient Double Head CNC Lathe Operations

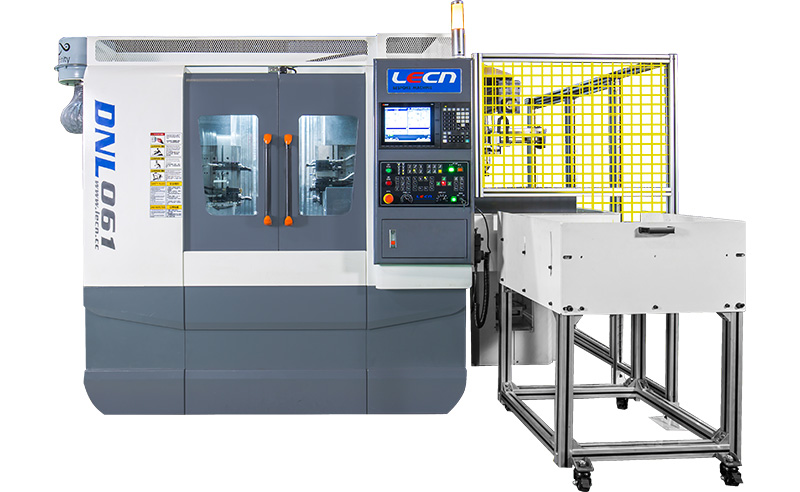

Double head CNC lathes are advanced machining tools that offer increased efficiency and productivity compared to their single head counterparts. These machines are equipped with two independent machining heads that can simultaneously work on a single workpiece, reducing cycle times and maximizing output. By leveraging the power of automation and precision control, double head CNC lathe have transformed the landscape of precision machining.

Factors to Consider for Efficient Double Head CNC Lathe Operations

To ensure efficient and successful operations with a double head CNC lathe, manufacturers should consider the following factors:

Workpiece Design and Compatibility: Optimize the design of the workpiece to take full advantage of the simultaneous machining capabilities. Ensure that the workpiece is compatible with the double head CNC lathe and can be securely held in place during machining.

Programming and Tooling: Develop accurate and optimized CNC programs that leverage the capabilities of the double head CNC lathe. Use appropriate tooling and cutting parameters to achieve the desired machining results.

Machine Calibration and Maintenance: Regularly calibrate the custom double head CNC lathe to maintain accuracy and repeatability. Follow the manufacturer's guidelines for maintenance and lubrication to ensure optimal performance and longevity of the machine.

Operator Training: Provide comprehensive training to machine operators to ensure they have a thorough understanding of the double head CNC lathe's functionalities and operating procedures. Proper training minimizes the risk of errors and maximizes productivity.

Maintenance and Care of Double Head CNC Lathes

Proper maintenance and care are crucial for the longevity and performance of double head lathes. Here are some essential maintenance practices:

Regular Cleaning: Keep the machine clean by removing chips, debris, and coolant residue. Regularly clean and lubricate the guide rails and ball screws to prevent buildup and ensure smooth operation.

Lubrication: Follow the manufacturer's recommendations for lubrication intervals and use the appropriate lubricants. Regularly inspect and replenish lubrication levels to prevent excessive wear and ensure optimal machine performance.

Inspection and Calibration: Periodically inspect critical components, such as spindle alignment, tool holders, and collets, for wear or damage. Perform regular calibration to maintain accuracy and repeatability.

Software Updates: Stay updated with the latest software versions provided by the machine manufacturer. Software updates often include performance enhancements, bug fixes, and new features that improve machine functionality.

Comparison with Single Head CNC Lathes

While double head CNC lathe offer significant advantages, single head CNC lathes still have their place in precision machining. Single head lathes are often preferred for simpler workpieces that do not require simultaneous machining. They are generally more cost-effective for low-volume production or when the workpiece design does not lend itself to parallel machining.

The choice between a double head CNC lathe and a single head lathe depends on the specific requirements of the machining project, production volume, and complexity of the workpiece.

Future Developments and Innovations

As technology continues to advance, we can expect further developments and innovations in double head CNC lathe technology. Manufacturers are likely to explore enhancements in automation, control systems, and tooling capabilities to further optimize precision machining processes. These advancements will enable even higher levels of productivity, accuracy, and versatility in the manufacturing industry.

Conclusion

Double head CNC lathes have revolutionized precision machining by offering increased productivity, improved accuracy, and enhanced versatility. These advanced machines have found applications in industries such as automotive, aerospace, medical devices, and electronics. By leveraging the power of automation and precision control, double head CNC lathes have transformed the manufacturing landscape, enabling manufacturers to achieve higher efficiency and produce high-quality, complex components. Embracing this technology opens up new opportunities for businesses to stay competitive in the ever-evolving world of precision machining.