Alloy C276 vs. Hastelloy C276: Understanding the Differences

In the realm of corrosion-resistant alloys, two terms that often appear are "alloy C276" and "Hastelloy C276." These terms are used interchangeably, leading to confusion among readers. In this article, we aim to clarify the differences and similarities between alloy C276 and Hastelloy C276, providing readers with a comprehensive understanding of these materials. By addressing the topic head-on, we will unravel the confusion and provide valuable insights for those seeking information about these corrosion-resistant alloys.

Clarifying Terminology: Alloy C276 and Hastelloy C276

a. Alloy C276: Alloy C276 is a nickel-molybdenum-chromium alloy with tungsten added for enhanced corrosion resistance. It is recognized by various industry standards and specifications, such as ASTM B574 and ASME SB574.

b. Hastelloy C276: Hastelloy C276 is a registered trademark of Haynes International Inc., a leading manufacturer of high-performance alloys. It refers to a specific formulation of the nickel-based alloy, which is known for its excellent corrosion resistance in a wide range of environments.

Chemical Composition and Properties:

a. Common Chemical Composition: Both alloy C276 and Hastelloy C276 have similar chemical compositions, consisting of nickel, molybdenum, chromium, and small amounts of iron, tungsten, cobalt, and other elements. The primary difference lies in the specific trace elements and impurities present in each manufacturer's formulation.

b. Corrosion Resistance: Alloy C276 and Hastelloy C276 exhibit exceptional corrosion resistance, particularly in aggressive environments containing acids, chlorides, and oxidizing agents. They can withstand harsh conditions, including sulfuric acid, hydrochloric acid, and seawater.

c. Mechanical Properties: The mechanical properties of alloy C276 and Hastelloy C276 are similar, including high tensile strength, excellent impact resistance, and good ductility. These properties make them suitable for various applications, including chemical processing, pollution control, and oil and gas industries.

Manufacturing and Standards:

a. Manufacturing: Alloy C276 and Hastelloy C276 are produced by different manufacturers. Alloy C276 is available from various sources and is not tied to a specific manufacturer. On the other hand, Hastelloy C276 is a proprietary alloy produced exclusively by Haynes International Inc.

b. Standards and Specifications: Both alloy C276 and Hastelloy C276 conform to industry standards and specifications. However, the specific certifications and approvals may vary depending on the manufacturer. It is crucial to refer to the appropriate standards and consult with reputable suppliers for the specific alloy requirements.

Applications and Usage:

a. Similar Applications: Alloy C276 and Hastelloy C276 are widely used in similar applications that require corrosion resistance and high-performance materials. Some common applications include chemical processing equipment, flue gas desulfurization systems, seawater handling, pulp and paper industry, and pharmaceutical manufacturing.

b. Brand Preference: Due to its brand recognition and long-standing reputation, Hastelloy C276 is often preferred by engineers and designers. However, alloy C276 from other manufacturers may offer similar performance characteristics and cost advantages.

Conclusion:

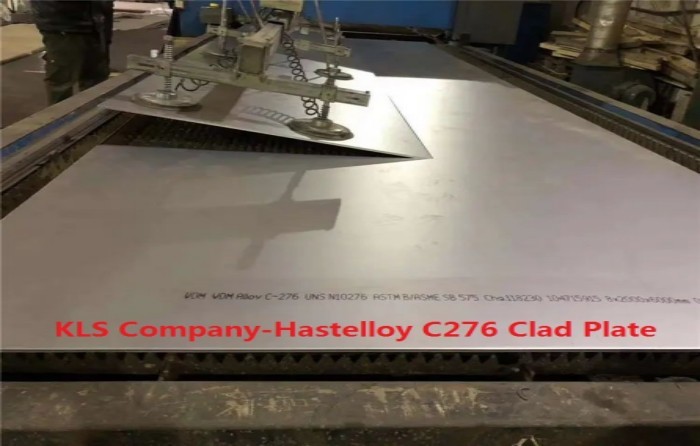

Alloy C276 and Hastelloy C276 refer to similar nickel-based corrosion-resistant alloys. The primary difference lies in the terminology, with Hastelloy C276 Clad sheet being a trademarked name for a specific formulation of the alloy produced by Haynes International Inc. Both alloy C276 and Hastelloy C276 possess similar chemical compositions, corrosion resistance, and mechanical properties, making them suitable for a wide range of demanding applications. It is essential to consider the specific standards, certifications, and requirements for your application and consult with reputable suppliers to select the appropriate alloy that meets your needs.