Applications of Custom Optical Windows

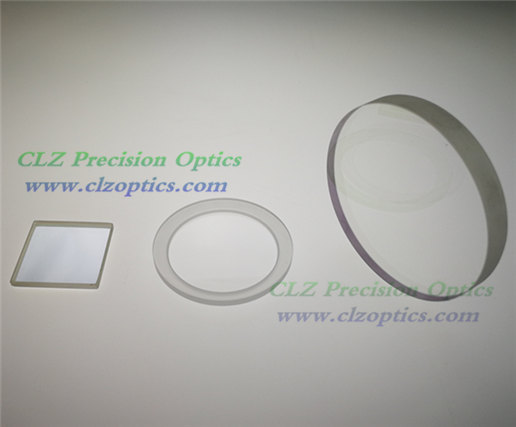

Custom optical windows are designed and manufactured to meet precise specifications that may not be readily available in standard options. These windows are crafted with exceptional precision, ensuring that they align perfectly with the intended application's demands. By working closely with optical engineers and manufacturers, customers can get optical windows optimized for their unique requirements, including size, shape, material, coatings, and performance characteristics.

Applications of Custom Optical Windows

Custom optical windows find application in various industries and fields, including:

A. Laser Systems

Precision laser systems often demand specific optical windows to maintain beam quality and prevent beam distortion. Custom windows play a crucial role in laser resonators, amplifiers, and frequency conversion systems.

B. Aerospace and Defense

In aerospace and defense applications, optical windows must withstand extreme conditions, including high speeds, temperature variations, and exposure to harsh environments. Custom solutions can be engineered to withstand these challenges.

C. Medical Devices

Medical imaging devices and diagnostics rely on precise optical components to deliver accurate results. Custom optical windows ensure optimal image quality and reliability in medical equipment.

D. Scientific Instruments

Research and scientific instruments often require custom optical windows to accommodate unique experimental setups and specialized measurement requirements.

See also:The Science Behind Engine Test Benches: Unlocking Performance and Efficiency

What is the passive seismic method?

Collaboration with Optical Engineers

Designing custom optical windows involves close collaboration between customers and optical engineers. The process typically follows these steps:

Requirements Gathering

Customers outline their specific requirements, including optical specifications, environmental conditions, and any size or shape constraints.

Optical Design

Optical engineers use advanced software tools to design custom solutions that meet the stated requirements.

Prototype Development

A prototype of the custom optical window is fabricated and tested to validate its performance.

Manufacturing and Quality Control

Upon successful prototype testing, the silicon windows are manufactured with strict quality control measures to ensure consistency and precision.

Conclusion

Custom optical windows offer tailored solutions for demanding applications where standard off-the-shelf options may not suffice. With the ability to optimize performance, select appropriate materials and coatings, and accommodate complex geometries, custom optical windows play a vital role in enhancing the efficiency and reliability of optical systems across various industries. Collaborating with optical engineers and manufacturers ensures the development of high-quality optical windows that precisely meet your precision needs.

See also:Unleashing the Potential of 3D Seismic Exploration.