Difference Between Heavy-Duty Hexagonal Mesh and Small Hexagonal Mesh

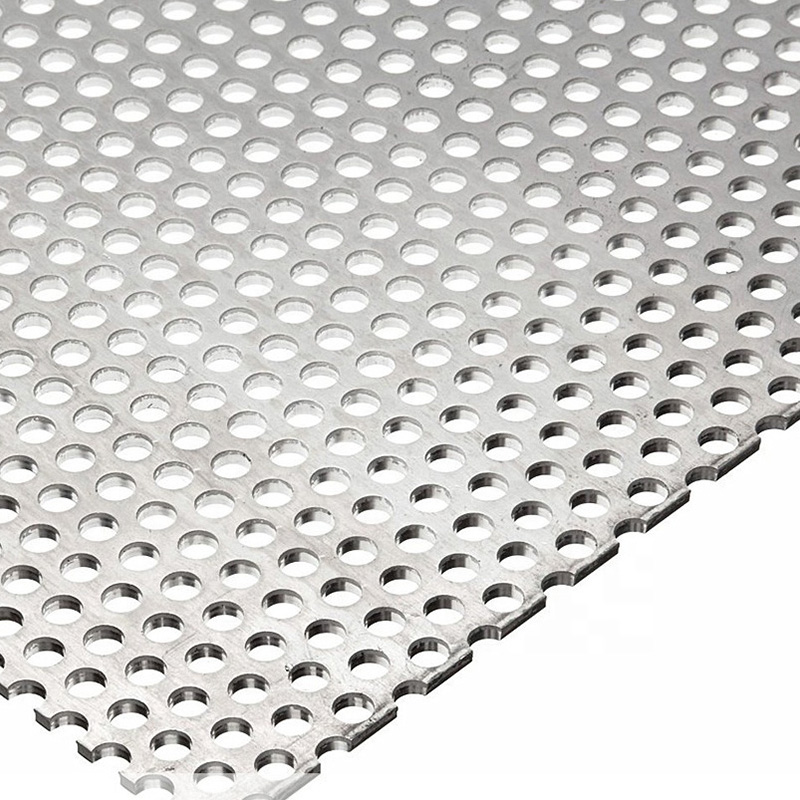

Hexagonal mesh is a type of wire mesh with twisted hexagonal openings, which can be classified into heavy-duty hexagonal mesh and small hexagonal mesh. While they may appear similar in appearance, their applications are quite distinct. Below, we will discuss the differences between the two:

Heavy-Duty Hexagonal Mesh Overview Heavy-duty hexagonal mesh is crafted by twisting galvanized steel wire or plastic-coated steel wire. It features hexagonal openings with wire diameters ranging from 2.0 millimeters to below 4.0 millimeters. This mesh is produced using heavy-duty vertical gabion mesh machines and is primarily used in hydraulic engineering. It is installed on riverbeds, slopes, bridge bottoms, and other locations to enhance and protect waterways, bridges, roads, railways, etc. Often, it is shaped into gabion boxes filled with stones, providing both protective and construction benefits. Additionally, it is considered an eco-friendly product commonly used for ecological conservation. The mesh openings for heavy-duty hexagonal mesh are typically 60x80mm, 80x100mm, and 100x120mm, with lengths ranging from 1 to 6 meters, widths of 1 to 2 meters, and heights of 0.17 to 1 meter.

Small Hexagonal Mesh Overview Small hexagonal mesh is made from thinner steel wire or plastic-coated wire, also featuring hexagonal openings. Wire diameters range from 0.4 millimeters to 1.8 millimeters. It is produced using lighter horizontal hexagonal mesh machines and is commonly used for landscaping and wall protection materials. Mesh openings for small hexagonal mesh come in sizes such as 1/2 inch, 3/4 inch, 1 inch, 2 inches, and 3 inches, among others.

Differences Between Heavy-Duty Hexagonal Mesh and Small Hexagonal Mesh

Production Machinery: The two types of hexagonal mesh are produced using different machines. Small hexagonal mesh is made using horizontal hexagonal mesh machines, which are simpler and lighter, resulting in lower acquisition costs. Heavy-duty hexagonal mesh, on the other hand, is produced using vertical hexagonal mesh machines, which are bulkier and more expensive.

See also:Applications of Galvanized Welded Wire Mesh in Various Industries

What is Expanded Metal? A Versatile Solution for Diverse Applications

Alloy C276 vs. Hastelloy C276: Understanding the Differences

What is nickel clad steel?

What is anti-fingerprint stainless steel?

How to Use Water Ripple Stainless Steel Sheets

How about stainless steel window screens?

Mesh Opening Sizes: Due to their different applications and production machinery, these meshes have distinct design specifications for mesh openings.

Wire Diameters: Both types of hexagonal mesh have their own suitable wire diameter ranges due to the limitations of production machinery.

Applications: Despite sharing the name "hexagonal mesh," they serve different purposes. Heavy-duty hexagonal mesh is commonly used with stones for hydraulic engineering, erosion control, or rockfall protection, whereas small hexagonal mesh is often used for reinforcing structures like walls and stairs, as well as in landscaping projects.

Cost and Pricing: Heavy-duty hexagonal mesh typically uses materials like galvanized wire with diameters of 2.0-4.0 millimeters or zinc-aluminum alloy wire for processing. In contrast, small hexagonal mesh usually utilizes black wire with diameters of 0.4-1.5 millimeters or around 1.0 millimeter galvanized wire, resulting in significant differences in raw material costs.

These differences highlight how heavy-duty hexagonal mesh and small hexagonal mesh are distinct in their characteristics and applications.

Exploring the Versatility and Applications of Metal Screen Mesh

What are Magnesia alumina brick used for?

A Comprehensive Guide to Aluminum Sheets

What Is Calcined Magnesite?

What is a Ductile iron pipe used for?

The Difference Between Dead-Burned Magnesite and Fused Magnesite with Large Crystals

Differences Between Inconel and Monel Safety Wire