How to manage your 3PL EDI integration with maximum efficiency

Third party logistics (3PL) providers provide additional support for specific phases of the shipping business, acting as a link between the outsourced distribution and fulfilment phases of the supply chain. While 3PL services have always been a key player in supply chain operations, their involvement is increasing as companies' sourcing, manufacturing and customer bases become progressively more multinational.

3PLs can provide warehousing, transportation, picking and packaging solutions - essentially covering any logistics service that a brand manufacturer cannot handle. Brand manufacturers tend to use 3PLs when their start-up facilities and systems outgrow their scale. for example, a start-up company selling cosmetics out of its garage might start getting a lot of orders on its e-commerce site. Suddenly, its manual processes are unable to meet the needs of its customers. Instead of buying its own fleet of warehouses and trucks, the startup might hire a 3PL to handle some or all of its warehousing, packaging and shipping across multiple states.

The complexity of 3PL integration

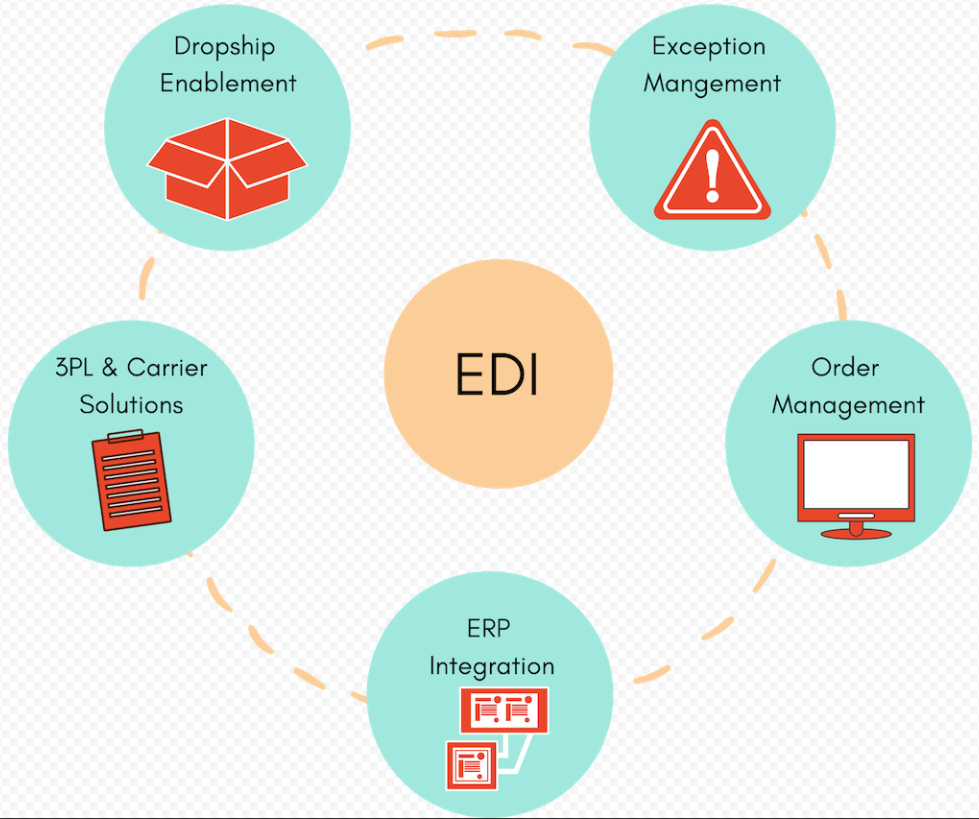

For most brand manufacturers, 3PL integration is an intricate network of EDI connections. But they don't have to be.

To build a successful relationship, brand manufacturers and 3PL providers must establish dynamic connections to share visibility of real-time data flows. That's why your 3PL must be integrated with your EDI system.

When properly implemented, 3PL EDI integration optimizes the efficiency through enhanced visibility and automation of retail order fulfillment. Brand manufacturers can also connect with a wider range of companies and trading partners, enabling them to offer more products to more consumers in the long run.

If a brand manufacturer works with multiple 3PLs, the burden of building and maintaining multiple custom integration environments can be significant. Using the old EDI system, they are creating point-to-point integrations for all transaction types for each 3PL. In some cases, integrations with fourth and fifth-party logistics systems will be required to further the roll-up.

The trick to simplifying this messy system is to set up transactions as efficiently as possible using a centralized EDI core rather than a point-to-point integration.

Why 3PL integration is so difficult

The main reason 3PL integration is often difficult to establish is that there is little standardization between 3PLs and their customers. In any EDI relationship, there is usually a leader and a follower. The leader dictates how the EDI transaction must be formatted. If the 3PL does not act as a leader, the brand manufacturer must do so, even if they are not used to doing so. Next is the ongoing confusion about the integration requirements between the two parties.

Some 3PLs will run the brand manufacturer'sparcel handling software in their own operating stations. In other words, they would log into the software and do the picking and packing in the brand manufacturer's system. This sounds like a good arrangement because it eliminates the need for integration - but it's not a scalable approach. If 3PL had done this for 10 different companies, it would have been impossible for them to understand the nuances of each company's system. As a result, the whole process becomes very error-prone.

Other 3PLs will try to integrate data with brand manufacturers. However, most 3PLs are small companies and lack the IT staff and expertise to properly incorporate new brand manufacturers. This leads to many back and forth conflicts with brand manufacturers as both sides try to find out who is responsible for the requirements and test the configurations they set up.

Whichever approach they took, 3PL was compromised to make the process as simple as possible for the brand manufacturer. So they did - but they didn't follow any standards in the process. Some 3PLs will accept whatever data format the manufacturer sends them, which forces them to create custom integrations for each company. By being so flexible with brand manufacturers, 3PLs actually create extra work for themselves because no integrations can be reused across relationships. Some 3PLs have tried to solve this problem by introducing their own APIs - but again, many 3PLs are small companies and lack the technical expertise for such ambitious ventures.

What is Chemical Cleaning in Piping?

Setting up a MySQL to S3 Pipeline with Vanus

How to manage your 3PL EDI integration with maximum efficiency

Common problems faced by companies often stem from the complexity of the 3PL logistics process itself, as well as the challenges of outdated EDI integration with old and new trading partners. Relying heavily on outdated forms of communication rather than automation can slow down essential information exchange, leading to frustration between companies. In addition, the failure to create a base EDI system that can scale as the business grows can create unnecessary work for individual teams.

By implementing an EDI system to help with the process and then choosing one party as the leader, you can more easily manage 3PL integration. Typically, it should be the 3PL provider, as their business remains the same as when they work with many different brand manufacturers. 3PLs should specify their requirements and let the brand manufacturers build the integrations needed to meet those requirements.

When you implement a cloud EDI solution such as eTower, your 3PL can simply publish their requirements in the system. From there, brand manufacturers can use self-service tools to meet the requirements. Both 3PLs and retailers can access the API if required.

Integrate EDI integration. With the specification API provided, you can reduce the number of single integrations by 90% compared to a peer-to-peer practice.

Leverage a platform with a thriving network of pre-connected trading partners. For example, eTower's ecosystem of pre-connected companies grows with each new user. This codifies partners and provides you with specific guidelines so you can jump straight to EDI data validation. Our network includes the full range of cross-border logistics operations from transport to operating stations to last-mile services.

Quickly join all new connections. Supply chain members that are not currently part of the eTower integration network can join quickly to eliminate delays. You and your 3PL provider can choose from a number of pre-configured code settings.

eTower: the ultimate EDI solution for 3PL integration

Most brand manufacturers using legacy EDI systems have built custom integration environments maintained by in-house teams of EDI experts, and in any case, this integration network is both complex and expensive to maintain. Most importantly, as your business continues to grow, it can be challenging to scale up. When you integrate with eTower, you don't have to build a point-to-point integration. eTower is the central integration point for your ERP or system of record as well as your 3PL. Connect to our platform once and leverage your existing 3PL and partner network to integrate all your EDI suppliers into one central hub.

Click here to speak to one of our EDI experts to find out more.

- Previous: API vs EDI – Choosing the ideal solution for 3PL

- Next: None