Metal Oxide Film Resistors: Precision and Stability in Electronic Circuits

Introduction:

Metal Oxide Film Resistors are fundamental electronic components known for their precision, stability, and reliability in a wide range of applications. This article aims to provide an in-depth exploration of Metal Oxide Film Resistors, their construction, characteristics, and the crucial role they play in ensuring accuracy and stability in electronic circuits.

Metal Oxide Film Resistors are passive electrical components designed to limit or control the flow of electric current within a circuit. They are constructed using a ceramic substrate coated with a thin film of metal oxide, typically tin oxide or ruthenium oxide. The metal oxide film acts as the resistive element, providing the desired resistance value.

Advantages of Metal Oxide Film Resistors:

Precise Resistance Values: Metal Oxide Film Resistors offer a high level of precision in resistance values. They are manufactured with tight tolerance ratings, ensuring accurate and consistent resistance performance.

Temperature Stability: These resistors exhibit excellent stability over a wide temperature range. They have low temperature coefficients of resistance (TCR), meaning their resistance values remain relatively unchanged with temperature variations. This characteristic is crucial in applications where temperature fluctuations can affect circuit performance.

Low Noise and Low Voltage Coefficient: Metal Oxide Film Resistors have low inherent noise levels, making them suitable for applications requiring minimal signal distortion, such as audio circuits and amplifiers. Additionally, they have a low voltage coefficient, meaning their resistance is less affected by changes in the applied voltage, ensuring stable performance across varying voltage levels.

High Power Handling Capacity: Metal Film Resistor can handle relatively high power levels due to their robust construction and efficient heat dissipation properties. This makes them suitable for power electronics applications where dissipating heat is critical.

Long-Term Reliability: Metal Oxide Film Resistors offer exceptional long-term reliability, maintaining their resistance values over extended periods of use. Their durable construction and resistance to environmental factors contribute to their reliability, ensuring consistent performance in various operating conditions.

See also:

Sourcing Reliable Electronic Components: A Buyer's Guide

Airless Spray Pump Filters: The Unsung Heroes of Precision Painting

Jump Starter, the Game-Changer in Vehicle Emergencies

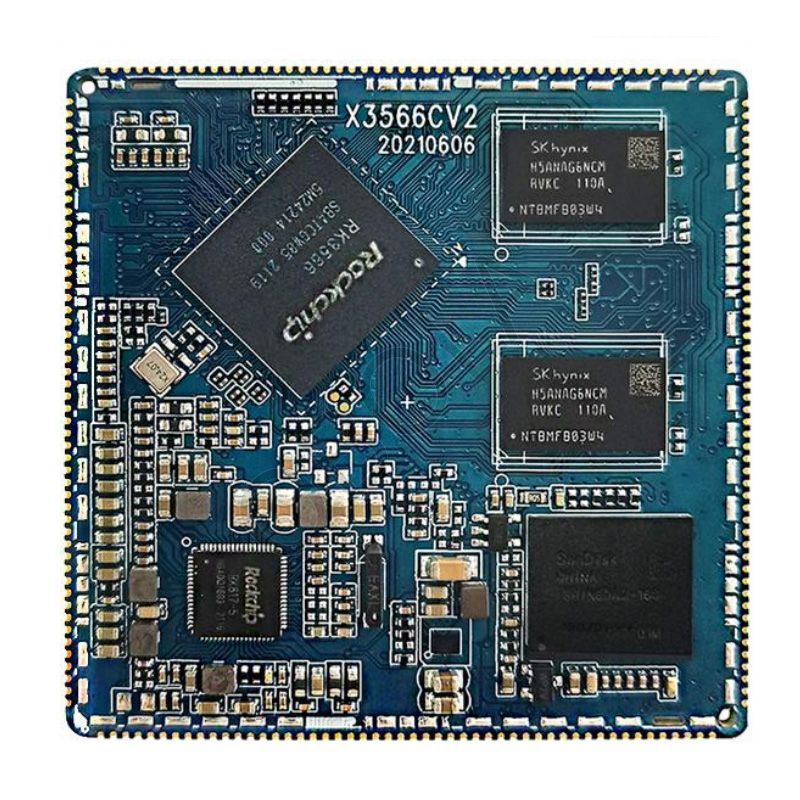

What sets Rockchip ARM Motherboards apart from others?

AC DC Welding Machines: Powering Precision and Versatility

What is the lead-acid battery?

Demystifying Types and Applications of Resistors

Applications of Metal Oxide Film Resistors

Metal Oxide Film Resistors find widespread use in numerous electronic applications, including:

Audio and Hi-Fi Systems: They are employed in audio amplifiers, equalizers, and speakers, providing precise voltage division and signal conditioning for high-quality sound reproduction.

Measurement and Test Equipment: Metal Oxide Film Resistors play a crucial role in precision measurement devices, such as multimeters, oscilloscopes, and signal generators, ensuring accurate readings and reliable circuit calibration.

Medical Devices: They are utilized in medical equipment, including patient monitoring systems, diagnostic instruments, and imaging devices, where precision and stability are essential for accurate measurements and reliable performance.

Industrial Control Systems: Metal Oxide Film Resistors are essential components in industrial automation and control systems, providing reliable current limiting, voltage regulation, and signal conditioning in manufacturing processes and robotics.

Telecommunications: They are employed in telecommunications equipment, such as switches, routers, and modems, for signal processing and line impedance matching, ensuring efficient and reliable communication.

Metal glazed Film Resistor is vital components in electronic circuits, offering precise resistance values, temperature stability, low noise, and high power handling capacity. Their reliability and long-term stability make them invaluable in various industries, including audio systems, measurement equipment, medical devices, industrial control systems, and telecommunications. With their ability to provide accurate and stable resistance performance, Metal Oxide Film Resistors continue to be an essential building block for engineers and designers, contributing to the overall precision and reliability of electronic systems.

See also:What’s the Difference Between HASL and HASL Lead-free in PCB?

What is the difference between RF cable and coaxial cable?

Phone Chargers: Powering Your Devices Anytime

Eye Bolts: The Reliable Workhorses of Various Industries

The Advantages of Stamp Hole Core Board SOMs

Factors to Consider When Choosing a Lithium-ion Golf Cart Battery

Understanding Heavy Duty Vehicle Batteries

- Previous: What is the difference between RF cable and coaxial cable?

- Next: None