Satin Finish vs. Other Stainless Steel Finishes

Satin Finish vs. Other Stainless Steel Finishes

Have you ever wondered about the various stainless steel finishes available for your projects? Choosing the right finish can significantly impact the aesthetics and durability of your stainless steel items. In this article, we will delve into the key differences between satin, matte, polished, and brushed stainless steel finishes, helping you make an informed decision based on your preferences and needs.

Satin Finish vs. Other Stainless Steel Finishes: Understanding the Basics

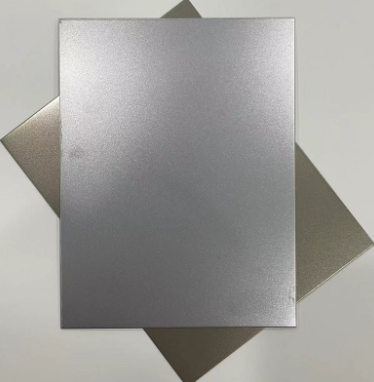

Satin Finish: A Subtle Elegance

A satin finish is characterized by its soft and muted appearance, making it a popular choice for modern designs. It showcases a low-gloss surface with a smooth texture, often achieved by sanding the stainless steel and then applying a protective layer. The result is a finish that effectively resists fingerprints, scratches, and smudges, making it suitable for high-traffic areas like kitchens and bathrooms.

Matte Finish vs. Satin Finish: The Distinctive Differences

Matte Finish: A velvety touch

The matte finish offers a unique velvety texture that sets it apart from satin. Unlike the slight gloss of satin, matte provides a completely non-reflective surface. This finish is achieved by abrasive blasting or chemical etching, giving stainless steel a modern, industrial appearance. Matte finish stainless steel is favored for its contemporary look and its ability to mask minor surface imperfections.

Satin Finish vs. Matte Finish: Which to Choose?

When choosing between satin and matte finishes, consider the overall ambiance you want to create. Satin finish offers a delicate gleam, while matte finish presents a bold, non-shiny appeal. Your choice should reflect the mood you're aiming for in your space.

Polished Finish vs. Satin Finish: The Battle of Shine

Polished Finish: A Brilliant Gleam

See also:With new construction, which type of plumbing is cheaper ...

10 Things to Consider When Buying Prefab Flat Pack Container Homes

The Benefits of Hot Rolled Steel Plate

The Benefits of Using Spiral Holes Carbide Rods: A Guide to Improved Cutting Performance

How Does reciprocating saw Blade Work?

Tungsten Buttons Bit: Carbide vs Steel - Which is Better?

Copper Clad Steel Plate: KLScladmetal's Best Offer

Polished stainless steel is known for its mirror-like shine and high reflectivity. Achieved through rigorous polishing processes, this finish is perfect for applications where aesthetics are paramount. Polished stainless steel adds a touch of luxury to spaces and complements contemporary, classic, or high-end designs.

Satin Finish vs. Polished Finish: Contrasting Allure

While satin finish exudes subtlety, polished finish commands attention with its dazzling gleam. The choice between the two depends on the level of sophistication you want to introduce to your design. Polished finish works remarkably well in lavish settings, while satin finish brings understated elegance.

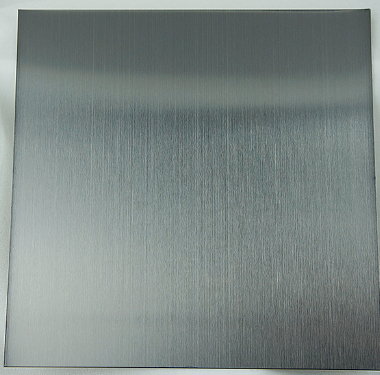

Brushed Finish vs. Satin Finish: Textured vs. Smooth

Brushed Finish: A Textured Beauty

Brushed stainless steel showcases distinctive parallel lines on its surface, created through brushing the metal with an abrasive material. This texture not only adds visual interest but also helps mask scratches and wear over time. Brushed finish finds its place in contemporary and industrial designs, as it offers a rugged yet stylish appearance.

Satin Finish vs. Brushed Finish: Contrasting Styles

Satin finish emphasizes smoothness, while brushed finish adds a touch of texture. The decision between the two comes down to personal taste and the overall design scheme. Satin finish is ideal for a sleek, modern look, while brushed finish brings a dash of ruggedness.

Our satin finish stainless steel

| Surface Finish | Satin |

| Surface Color | Can be done as Silver, Gold, Black, Gold Rose, Bronze, Brown, Nickle Silver and so on, or customer’s color. |

| Raw Material | 201/304/316L/430/441/443 |

| Material Thick | 0.5 to 3.0mm |

| Material Width | ≤ 1500mm, ≤ 2000mm |

| Material Length | ≤ 6000mm |

| Standard Size | 1219x2438mm(4ftx8ft),1219x3048(4ftx10ft),1500/1524x2438mm(5ftx8ft),1500/1524x3048(5ftx10ft) |

| Purchase qty | The minimum quantity for 0.5mm to 1.0mm thick is 100 pcs, other thicknesses can be ordered as 50pcs one time. |

| Purchase sample | Satin/Gold/304/1219X2438X1.0/100PCS.....PRICE/PC |

Tungsten Carbide Rod Price: High Quality vs. Budget-Friendly

409 Stainless Steel Plate vs Other Alloys: Ultimate Comparison

What is the process of Desulfurizing?

Affordable tungsten carbide drill bits: Are quality compromised?

4 Tips to Choose a Stainless Steel 304

The Benefits of Using carbide sleeve: Everything you need to know

How is Steel Pipe Manufactured?

- Previous: With new construction, which type of plumbing is cheaper ...

- Next: None