The Benefits of Using 50 Mining And Quarry Woven Wire Screen: A Comprehensive Guide

**The Benefits of Using 50 Mining And Quarry Woven Wire Screennsive Guide**.

1. What is 50 mining and quarry woven wire screen?

2. What are the benefits of using 50 mining and quarry woven wire screen?

3. How can 50 mining and quarry woven wire screen improve mining and quarry operations?

**1. What is 50 mining and quarry woven wire screen?**.

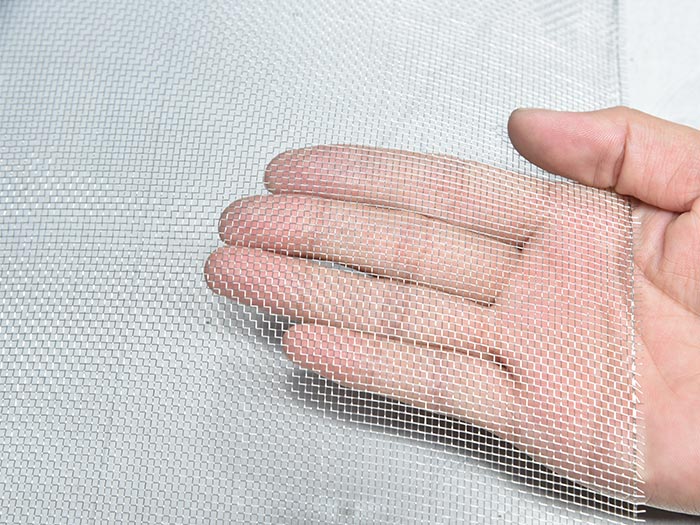

50 mining and quarry woven wire screen is a type of screen made from high-quality woven wire mesh. It is specifically designed for use in the mining and quarry industries to separate and filter materials such as rocks, gravel, and sand. The number "50" refers to the mesh size of the screen, indicating the number of openings per inch. This screen is durable, flexible, and corrosion-resistant, making it ideal for heavy-duty applications in harsh environments.

**2. What are the benefits of using 50 mining and quarry woven wire screen?**.

- Improved efficiency: The 50 mining and quarry woven wire screen allows for efficient screening and sorting of materials, resulting in higher productivity and reduced downtime.

- Durability: This screen is made from high-quality materials that can withstand heavy loads and abrasive materials, ensuring long-lasting performance.

See also:What Is Riprap and Why Is It Important?

10 Questions You Should Know About Riprap vs. Gabion: Understanding the Key Differences

How Does a Portable Solar Charger Work?

Top Benefits of Pipe Fencing for Horse Safety and Durability

How Does Electric Vehicle Charging Infrastructure Work?

The Advantages of Installing Plastic Coated Fencing Mesh

How to Choose the Right Riprap Wall Construction?

- Versatility: The screen can be used for a variety of applications in the mining and quarry industries, including screening gravel, separating rocks, and classifying materials.

- Cost-effective: Investing in 50 mining and quarry woven wire screen can save money in the long run by reducing maintenance costs and improving overall operational efficiency.

**3. How can 50 mining and quarry woven wire screen improve mining and quarry operations?**.

- Increased productivity: The use of this screen can streamline the screening process, allowing for faster and more efficient operations.

- Enhanced safety: By effectively filtering materials, the screen helps to reduce the risk of accidents and injuries in mining and quarry environments.

- Improved material quality: The screen ensures that only the desired materials pass through, resulting in higher-quality products.

- Environmental protection: The screen helps to minimize waste and contamination, promoting sustainable mining and quarry practices.

- Simplified maintenance: The durable construction of the screen requires minimal maintenance, saving time and resources for mining and quarry operators.

Are you interested in learning more about 45 Mining And Quarry Woven Wire Screen supplier, 45 Quarry Screen Mesh wholesale? Contact us today to secure an expert consultation!

See also:How to Choose the Best Graco Suction Filters for Export?

Why is Industrial Filtration Mesh Better?

When to Use epoxy coated mesh exporter?

4 Tips to Select the Best Portable Solar Panels

What is the best metal for an outdoor gate?

Red Brand Wire

9 Tips & Tricks For High Tensile Fence Setup