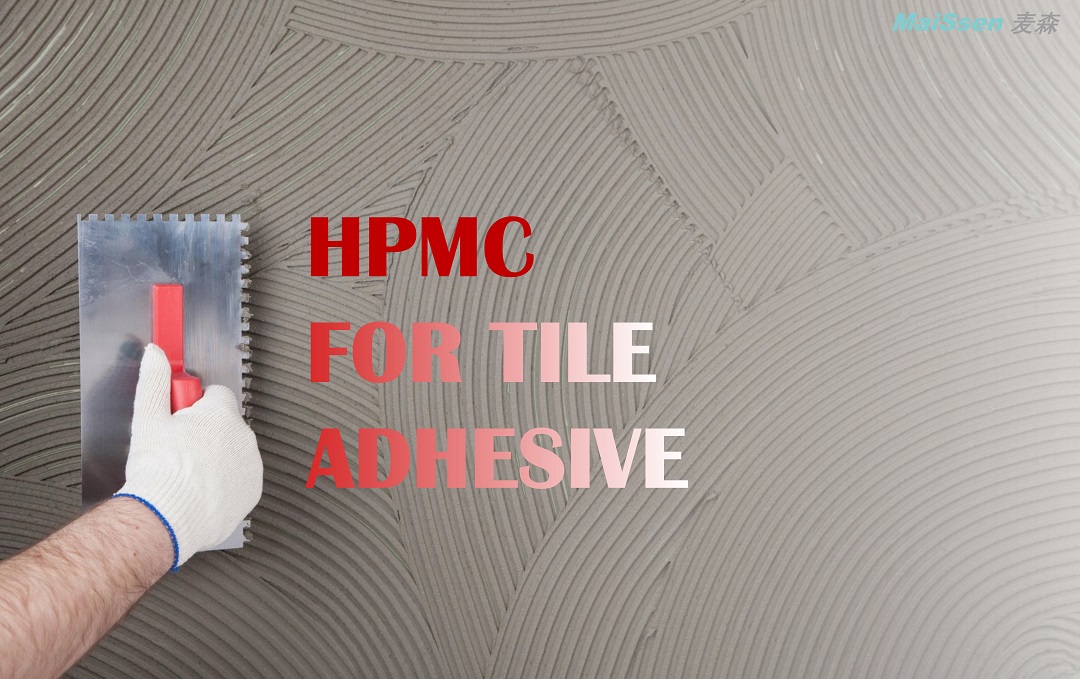

The Key Role of HPMC in Tile Adhesives

HPMC, or Hydroxypropyl Methylcellulose, plays a crucial and multifaceted role in the formulation and performance of tile adhesives. This versatile compound is a hydrocolloid derived from cellulose and is employed in various industries, including construction. In the context of tile adhesives, HPMC serves as an essential additive that contributes to the adhesive's overall effectiveness and quality.

One of the primary functions of HPMC in tile adhesives is its role as a thickener and rheology modifier. By adjusting the viscosity and flow properties of the adhesive mixture, HPMC enhances its workability and spreadability, making it easier for installers to apply the adhesive evenly onto surfaces. This improved workability ensures that tiles can be properly positioned and aligned during installation.

Moreover, HPMC acts as a water retention agent. It helps to control the rate at which water evaporates from the adhesive mixture, allowing the cementitious components to hydrate adequately. This prolonged hydration process is crucial for the development of sufficient bond strength between the tile and the substrate. Additionally, the water retention capability of HPMC prevents premature drying of the adhesive, reducing the likelihood of cracking and ensuring a more robust and durable tile installation.

Ensuring Scaffold Plank Height Safety: Understanding Board Wear and How to Prevent It

The Perfect Solution for Indoor and Outdoor Playgrounds

Exploring the Advantages of Framing Membrane Structures

Railway Continuous Beam Bridge Bearings: Ensuring Stability and Safety

Dive into Elegance: 8 Best Swimming Pool Mosaic Ideas

What is the purpose of dams and their role in water management?

Expanded Metal vs. Perforated Metal

HPMC also contributes to the adhesive's improved adhesion and cohesion properties. It enhances the adhesive's ability to adhere to both the tile and the substrate by promoting the formation of a strong and continuous bond. Furthermore, HPMC aids in reducing the risk of shrinkage and cracking during the drying and curing phases, which can lead to weakened adhesion and compromised tile installations.

In terms of sag resistance, HPMC helps prevent tiles from slipping or sliding out of place before the adhesive sets. This is especially important when installing wall tiles or tiles on vertical surfaces. The improved sag resistance offered by HPMC ensures that the tiles remain in their intended positions until the adhesive has fully cured.

Another notable advantage of incorporating HPMC into tile adhesives is its compatibility with a wide range of additives and raw materials. This compatibility allows manufacturers to fine-tune the adhesive formulation to meet specific performance requirements, such as adjusting setting time, open time, and final bond strength.

In summary, HPMC plays a key role in tile adhesives by providing essential properties such as thickening, water retention, improved adhesion, sag resistance, and compatibility with other components. These qualities collectively contribute to the overall quality and reliability of tile installations, ensuring long-lasting and aesthetically pleasing results. As a result, HPMC has become an indispensable ingredient in the formulation of modern tile adhesives, enabling efficient and effective tile installations in various construction applications.

See also:Quality and Durability of Granite Headstones

Which industries commonly use GFS tanks, and what are the benefits of using them for storage purposes?

HDPE Pipe Floats: The Ultimate Guide to Buoyancy Solutions

Advantages and Applications of Threading Pipe

What is the use of PP fiber in concrete?

Choosing the Right Star Picket for Your Project

How Fog Fountains Work

- Previous: Can CDX plywood be used for roofing?

- Next: How Fog Fountains Work