What are composite panels used for?

Introduction

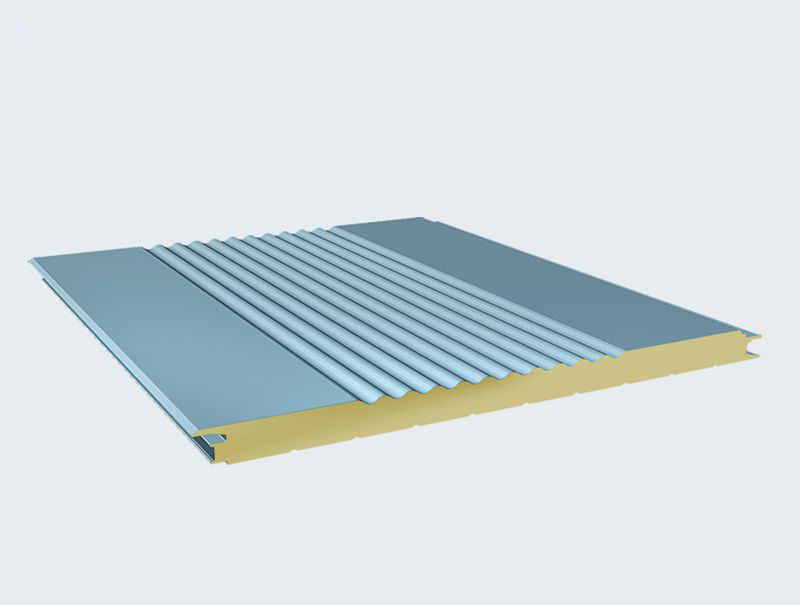

Composite panels, also known as sandwich panels, have rapidly gained popularity in various industries due to their versatility, durability, and cost-effectiveness. These panels are constructed by layering different materials, often including a core material and outer facings, to create a single, cohesive unit. The combination of materials allows composite panels to exhibit specific properties that make them ideal for a wide range of applications. In this article, we will explore the diverse uses and applications of composite panels and their significance in today's world.

Building and Construction

Composite panels are extensively used in the building and construction industry. They offer a myriad of advantages, making them a preferred choice for various applications in both residential and commercial construction projects.

a. Wall Cladding: Composite panels serve as excellent cladding materials for building exteriors. They are lightweight, easy to install, and provide insulation and protection from weather elements. The panels can also mimic the appearance of natural materials, such as wood or stone, enhancing the aesthetic appeal of structures.

b. Roofing: Composite panels are widely used for roofing, especially in industrial and commercial buildings. Their insulating properties help maintain temperature control and energy efficiency within the building. Additionally, they are known for their water-resistance and durability.

c. Insulation: Sandwich panels are employed as thermal and sound insulation materials within walls and roofs. The insulating core of these panels can effectively regulate indoor temperatures, reduce energy costs, and provide acoustic insulation.

d. Partitions and Ceilings: Composite panels are used in interior applications like partition walls and suspended ceilings. They offer a clean and modern look while providing acoustic insulation and fire resistance when needed.

Transportation

Composite panels play a significant role in the transportation industry, contributing to the development of lighter and more fuel-efficient vehicles.

a. Aircraft: The aerospace sector widely utilizes composite panels for aircraft construction. These panels are lightweight, durable, and possess excellent strength-to-weight ratios. The reduction in weight helps enhance fuel efficiency, making them an ideal choice for the aerospace industry.

b. Automotive: In the automotive industry, composite panels are used for the construction of vehicle bodies, especially in electric and hybrid vehicles. The lightweight nature of these panels improves the overall efficiency and range of electric vehicles while maintaining structural integrity.

Furniture and Interior Design

Composite panels have found their way into the world of interior design and furniture manufacturing.

a. Cabinets and Furniture: Furniture manufacturers use composite panels to create cabinets, shelves, and tables. These panels are favored for their durability, resistance to moisture, and the ability to achieve various finishes, from glossy to matte.

b. Decorative Surfaces: Composite panels are also used for decorative wall panels, doors, and other interior surfaces. They offer a wide range of design options, including various colors, textures, and patterns.

Industrial Applications

Industrial settings frequently make use of composite panels for diverse purposes.

a. Cleanrooms: Composite panels are the preferred choice for constructing cleanrooms in pharmaceutical and semiconductor industries. The panels provide a controlled environment with precise temperature, humidity, and particle control.

See also:Expanded Metal vs. Perforated Metal

Quality and Durability of Granite Headstones

Which industries commonly use GFS tanks, and what are the benefits of using them for storage purposes?

HDPE Pipe Floats: The Ultimate Guide to Buoyancy Solutions

Advantages and Applications of Threading Pipe

What is the use of PP fiber in concrete?

Choosing the Right Star Picket for Your Project

b. Cold Storage: In the food and beverage industry, composite panels are used to build cold storage facilities, ensuring airtight and thermally efficient environments to preserve products at low temperatures.

Transportation Containers

Composite panels are essential in the production of transportation containers like shipping containers and refrigerated trailers. They offer excellent strength, durability, and insulation properties, ensuring the safe and efficient transport of goods.

Marine Industry

The marine industry takes advantage of composite panels for boat construction, as they are resistant to corrosion and provide buoyancy. Composite panels are commonly used for boat hulls, decks, and cabin interiors. Their lightweight properties also help improve the overall efficiency and performance of boats.

Renewable Energy

Composite panels have made their way into the renewable energy sector, contributing to the development of energy-efficient products.

a. Solar Panels: Some solar panels incorporate composite materials in their construction to enhance durability and reduce the weight of the panel. Lighter panels are easier to transport and install, making solar power systems more accessible.

Signage and Displays

Composite panels are popular choices for signage and displays due to their lightweight and durable properties. They can be customized with high-quality prints and graphics, making them ideal for advertising and promotional materials.

Agriculture and Farming

Agricultural buildings and facilities often employ composite panels for their construction. These panels provide insulation, allowing for controlled temperature environments suitable for various agricultural activities, such as livestock farming and crop storage.

Sports and Recreational Equipment

The sports and recreation industry utilizes composite panels in the production of equipment like kayaks, paddleboards, and snowboards. The lightweight and durable nature of these panels ensures the longevity and performance of these products.

Healthcare

In the healthcare sector, composite panels are used in the construction of medical facilities and cleanrooms. They provide a sterile and controlled environment, which is crucial in healthcare settings to maintain hygiene and safety standards.

Renewable Energy

As the world increasingly embraces renewable energy sources, composite panels have found a place in the production of wind turbine blades. These panels offer the necessary strength-to-weight ratios and durability required for efficient wind energy generation.

Conclusion

Composite panels have revolutionized various industries due to their versatility, durability, and adaptability. Their unique combination of materials and properties makes them a popular choice for applications in construction, transportation, furniture, interior design, industrial settings, and more. As technology advances and the demand for lightweight, energy-efficient, and environmentally friendly solutions continues to grow, composite panels are likely to play an even more significant role in shaping the future of various industries. Their applications are wide-ranging, and their impact is undeniable, making composite panels an essential part of modern manufacturing and design. We also have pu panel wall for sale, if you need, please contact us.

How Fog Fountains Work

Can CDX plywood be used for roofing?

What is the difference between ceramic mosaic and glass mosaic?

Understand The Different Types of Plywood for Your Furniture

What are the uses of prestressed steel strands and how to use them correctly

What is MDF medium density Fibreboard?

How to apply PU waterproofing glue on a concrete roof?