What is the difference between Galvalume and galvanized steel?

When purchasing steel products for your home, business, barn, or any other structure, it is crucial to have a thorough understanding of the type of material you are investing in. For instance, for roofing, the most common steel materials used are "Galvalume steel" and "Galvanized steel." These materials have similar applications but their properties can be different. It is important to get familiarized with these terms in order to make an informed decision regarding your roofing needs.

By definition, these two metals are not all that different. Yet, the advantages and disadvantages of Galvalume and galvanized metal differ greatly, including how long each lasts, how each performs, and other factors.

Galvalume steel and galvanized steel are both popular types of steel used in various industries, but they differ in terms of their composition and performance. Galvalume steel refers to a sheet of metal that has been coated in galvalume; a carbon steel base product is repeatedly hot-dipped into the alloys of aluminum and zinc. Whereas, galvanized steel refers to a sheet of metal that has been coated with zinc via hot-dipping.

To understand the difference between galvalume steel andgalvanized steel, let us first understand these terms individually.

Galvalume Steel - Meaning, Features, and Applications

Galvalume steel is a type of coated steel that has a combination of zinc, aluminum, and silicon applied to its surface. The coating is applied to the steel substrate through a continuous hot-dip process, creating a tightly bonded alloy layer that protects the underlying steel from corrosion.

Some of the features of Galvalume steel include:

Corrosion resistance: Galvalume steel has excellent corrosion resistance due to its unique composition of aluminum, zinc, and silicon. This coating provides long-term protection against rust and corrosion, making it an ideal material for outdoor applications such as roofing and siding.

Durability: Galvalume steel is highly durable and can withstand harsh weather conditions, such as extreme temperatures and high winds. It is also resistant to damage from hail, making it a popular choice for roofing and paneling.

Aesthetic appeal: Galvalume steel has a unique look that is highly sought after in modern architecture. Its metallic sheen provides a sleek, modern appearance that is ideal for contemporary designs like cabinetry, pipes, and computer and refrigerator cases.

Low maintenance: Galvalume steel requires minimal maintenance, making it a cost-effective solution for building gutters and downspouts. They can withstand heavy rain and snowfall without rusting or corroding. Its durability and corrosion resistance means it does not need to be painted or coated to protect it from the elements.

Applications of Galvalume Steel:

Galvalume steel has a wide range of applications due to its excellent corrosion resistance, durability, and aesthetic appeal. Some of the most common applications of Galvalume steel include

Roofing: Pre-painted galvalume steel is a popular material for roofing due to its ability to withstand harsh weather conditions and its long-lasting durability. It is commonly used in residential, commercial, and industrial roofing applications.

Siding: Galvalume steelis also used in siding applications due to its resistance to fading, chalking, and cracking. It is commonly used in residential, commercial, and industrial siding applications.

Construction: Galvalume steel is used in a variety of construction applications, including structural framing, decking, and fencing. Its durability and corrosion resistance make it an ideal material for use in harsh environments.

Appliances: Galvalume steel is used in the manufacturing of appliances such as cases and sheets of refrigerators, ovens, and washing machines due to its durability, corrosion resistance, and aesthetic appeal.

See also:Alloy C276 vs. Hastelloy C276: Understanding the Differences

What is nickel clad steel?

What is anti-fingerprint stainless steel?

How to Use Water Ripple Stainless Steel Sheets

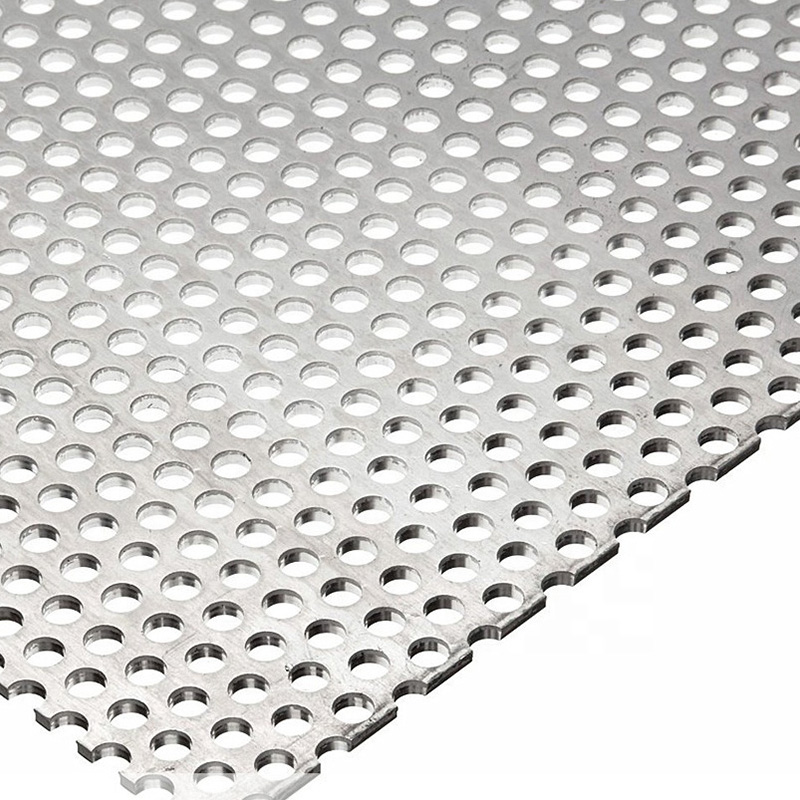

How about stainless steel window screens?

Exploring the Versatility and Applications of Metal Screen Mesh

What are Magnesia alumina brick used for?

Solar panels: Galvalume steel is used in the construction of solar panels due to its excellent corrosion resistance and durability. It is commonly used in the framing and mounting of solar panels.

Overall, Galvalume steel coil is a versatile material that can be used in a wide range of applications due to its durability, corrosion resistance, and aesthetic appeal.

Galvanized Steel - Meaning, Features, and Applications

Galvanized steel is a type of steel that has a zinc coating applied to its surface. This coating is applied through a hot-dip process, where the steel is immersed in a bath of molten zinc, which creates a tightly bonded layer of zinc on the surface of the steel.

Here are some features of galvanized steel:

Durable: Galvanized steelis highly durable and can withstand extreme weather conditions and mechanical stress.

Sustainable: Galvanized steel is a sustainable building material since it can be recycled, and the zinc coating can provide an additional layer of protection to steel products, extending their lifespan.

Low maintenance: Galvanized steel requires minimal maintenance, making it a cost-effective solution for automotive industry products like chassis, body panels, and suspension components. The zinc coating provides protection against rust and corrosion, eliminating the need for painting or coating.

Aesthetic appeal: Galvanized steel has a distinctive silver-gray appearance that can provide a classic to fences, rails, guardrails, gates, and more.

Application of Galvanized Steel

Galvanized steel is a versatile material that can be used in a wide range of applications due to its excellent corrosion resistance and durability. Some of the most common applications of galvanized steelinclude

Construction: Galvanized steel coils widely used in the construction industry for structural framing, roofing, fencing, and decking due to its strength, durability, and resistance to corrosion.

Automotive: Galvanized steel is commonly used in the automotive industry for body panels, chassis, and other structural components due to its ability to resist corrosion and provide long-lasting durability.

Electrical: Galvanized steel is used in electrical applications such as electrical conduits, cable trays, and enclosures due to its strength, durability, and resistance to corrosion.

Agriculture: Galvanized steel is commonly used in agriculture for fencing, livestock enclosures, and storage buildings due to its strength, durability, and resistance to rust and corrosion.

Industrial : Galvanized steel pipe and galvanized steel sheet are used in various industrial applications, including industrial machinery, storage tanks, and pipe systems, due to its strength, durability, and resistance to corrosion.

Overall, galvalume and galvanized steel are good corrosion preventers and are utilized in a wide range of industries, from roofing and siding to automobile manufacture and construction. The decision between the two will be determined by considerations such as the application, the climate in which the steel will be utilized, and the intended look and cost.

A Comprehensive Guide to Aluminum Sheets

What Is Calcined Magnesite?

What is a Ductile iron pipe used for?

The Difference Between Dead-Burned Magnesite and Fused Magnesite with Large Crystals

Differences Between Inconel and Monel Safety Wire

what are the two types of magnets?

The Most Common Super Alloy and Its Applications